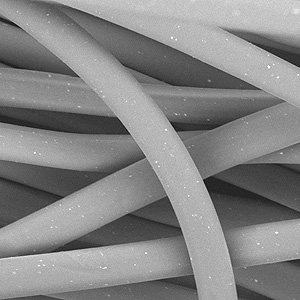

Polyester is the most versatile, most cost-effective and most widely used filter media for dust collection. It is strong, abrasion resistant can work up to 150°C and has good resistance to common acids, solvents and oxidizing agents. Its one weakness is a tendency to hydrolyze which results in a loss of strength and toughness as the fibers break down and turn to powder.

Polyester, being a 'commodity' fiber, is available in a significant range of deniers (effectively diameters) and so a wide range of needlefelt products can be designed to match the demands of the filter; from very high collection efficiency (with very fine fibers) to low efficiency products (using coarse fibers) where flow is more important than collection.

A wide variety of chemical and thermal treatments are available for polyester, the most common being superglaze to improve dust release and liquid repellency to assist with sticky dusts.

ACIDS – GOOD

ALKALIS – FAIR

OXIDIZING AGENTS – GOOD

HYDROLYSIS – POOR

SOLVENTS – GOOD

Avoid strong alkali and acid environments at elevated temperatures – the most versatile of the low temperature fibers, used in the cement and quarry, metal processing, flour and wood industries.

Maximum Continuous in Dry Conditions: 150°C / 302°F

Maximum Surge in Dry Conditions: 160°C / 320°F

The data shown and statements made in this document are representative properties and characteristics. Actual results may differ, depending on use. Lydall makes no warranty, express or implied, concerning results which may be obtained by using the product.