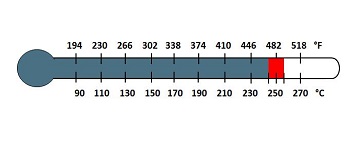

Polyimide is a high temperature fiber which under dry conditions can be operated up to 230°C.

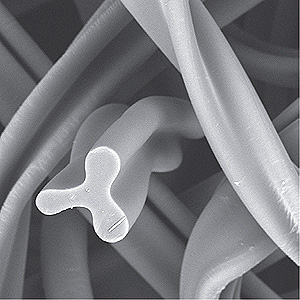

A common Polyimide fiber is P84®. This fiber benefits from a tri-lobal cross section which greatly enhances its filtration efficiency to the point that it is sometimes used with much less expensive fibers to boost dust collection. In this application it usually forms a cap on the surface of the felt to exploit this property effectively.

It is a fiber with good chemical and thermal resistance. Some care is needed with oxidizing agents such as NO2 and the fiber can be sensitive to hydrolytic attack in hot wet conditions.

ACIDS – GOOD

ALKALIS – GOOD

OXIDIZING AGENTS – FAIR

HYDROLYSIS – FAIR

SOLVENTS – GOOD

Improved hydrolysis resistance compared with m-aramid fibers – irregular cross section enhances filtration efficiency – used in power generation, incinerators and the cement industry.

MAXIMUM CONTINUOUS IN DRY CONDITIONS: 245°C / 473°F

MAXIMUM SURGE IN DRY CONDITIONS: 255°C / 491°F

The data shown and statements made in this document are representative properties and characteristics. Actual results may differ, depending on use. Lydall makes no warranty, express or implied, concerning results which may be obtained by using the product.