Cure-In-Place-Pipe is a cost-effective, less invasive alternative to replacing failing underground infrastructure. Mature technology now—over 50-years strong—has many companies worldwide utilizing this trenchless technology and methodologies. CIPP lining uses textile liner tubes and liquid resins.

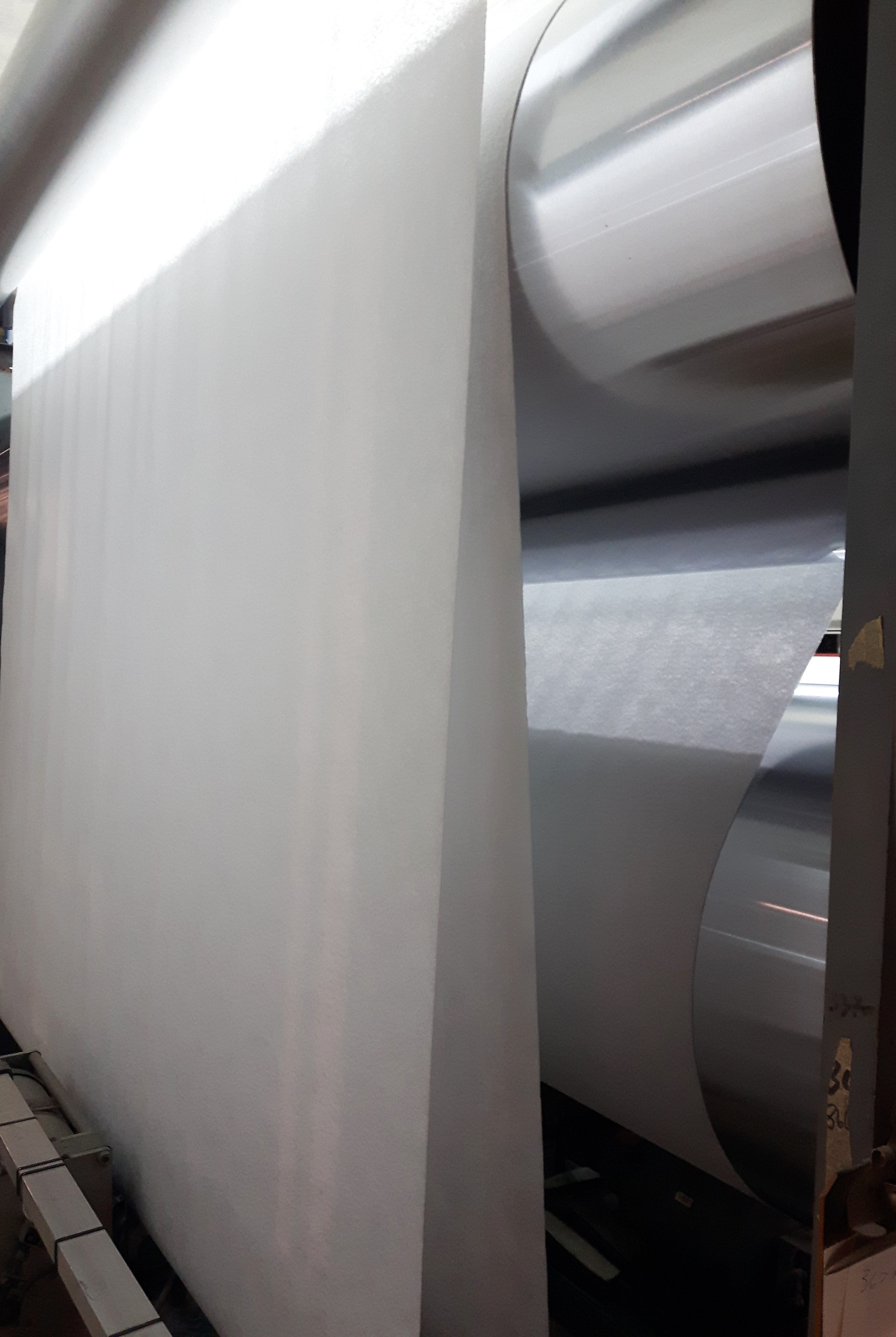

Needlefelts known for its high-percent void volume is the perfect resin-carrier medium. Specialized needlefelts—with & without support systems and basefelt & polymer extrusion-coated for impermeability—are formed into CIPP tubes. Tube liner is then impregnated with resin mixture and is installed and cured in place. The installed CIPP liner is a new pipe within a host pipe.

Our CIPP division advantageously complements our multitude of nonwoven product platforms by offering an array of options in the development of technical substrate fabrics. Our technique of thermoplastic-film extrusion or that of coating—i.e. depositing a polymer (PP, PVC, TPU, HDPE, etc.) on a needlefelt/nonwoven or woven/knit and other substrates—the CIPP division has the capabilities to design, test and manufacture innovative films and composites for a multitude of applications.

- Durable Long-term Solution to the Problem of Deteriorating Water and Wastewater Pipelines and Conduits

- Strong, Smooth and Corrosion-resistant Coatings Eliminate Costly Pinholes & Delamination

- Coated substrate (including felt/fberglass composites)

- Clear or solid color flm/tape

- Transparent or solid color inflatable bladders

- Coating suitable for sewer & potable water applications

- Vertically integrated